Many customers decided to buy an HP indigo to improve their production capacity. However, after doing the first printing test, they found that the ink didn't have a good adhesion with the ordinary substrates. Then, what happened ?

We realize that only having a good equipment is not enough to produce outstanding products. Some small factors in the production can also influence the result. One of the important factors is the coating on the substrates.

Why do the substrates need special treatment before printing on HP Indigo?

There are two main reasons:

1. Inking performance: HP Indigo use E-Ink which has strict requirement in inking performance and it is varied in different substrates.

2. Adhesion performance:For the same reason, different substrates has different adhesion performance.

To solve the above problems, printing companies began to use printing substrates with special coating treatment. There are two coating types that are suitable for HP Indigo: water-based coating and oil-based coating. Currently, water-based coating is more popular for its good adaption on decorative papers including cardboard, pearl paper, powder paper with transparent and environment-friendly features.

Introduction of BNK Digital Printing Primer

BNK water-based digital printing primer is suitable for E-ink and has different types to deal well with the e-ink adhesion on different substrates from paper to film, including PVC, PET, BOPP, synthetic paper, gold and silver cardboard, etc. Our primers have four advantages.

1. Rub-resistant and waterproof

The coating solution has the characteristics of strong ink adhesion, rub resistance , scratch resistance, and water resistance (boiled 3M tape test OK).

2. Wide-range adaptation in substrates

It can be applied on paper, film or metallic film, etc.

3. Good adaption in different coating equipment

It is adaptable for different offline coating equipment, such as Gravure flexo machine, laminating machine, and oiling machine can all be faisable, and the drying temperature is low ( 60°C or above is enough).

4. Cost effective

The dosage is small and it can lower the cost. The dry coating amount is 0.3-0.5g/㎡.

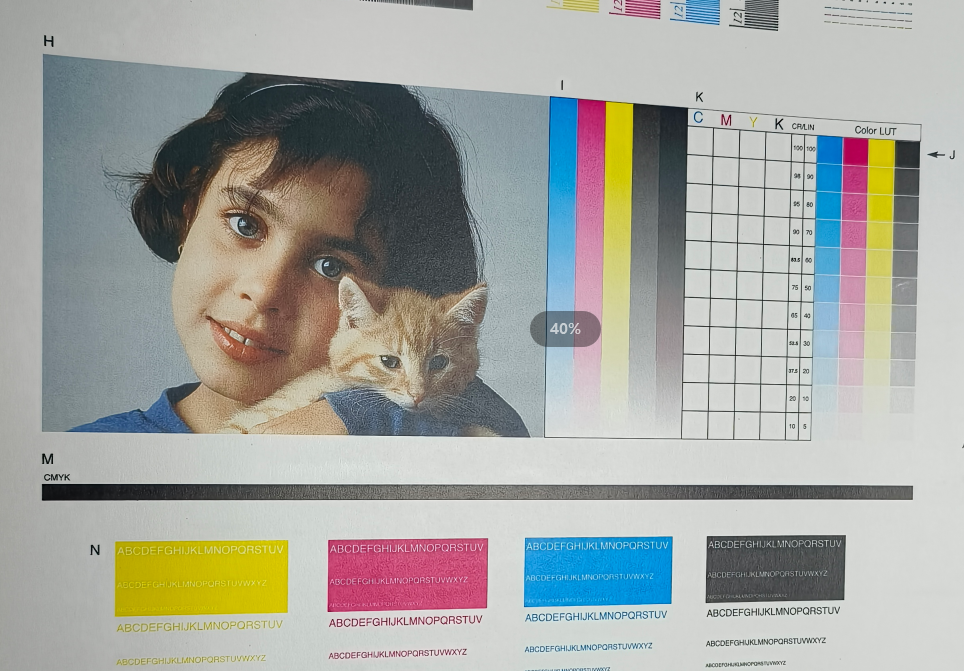

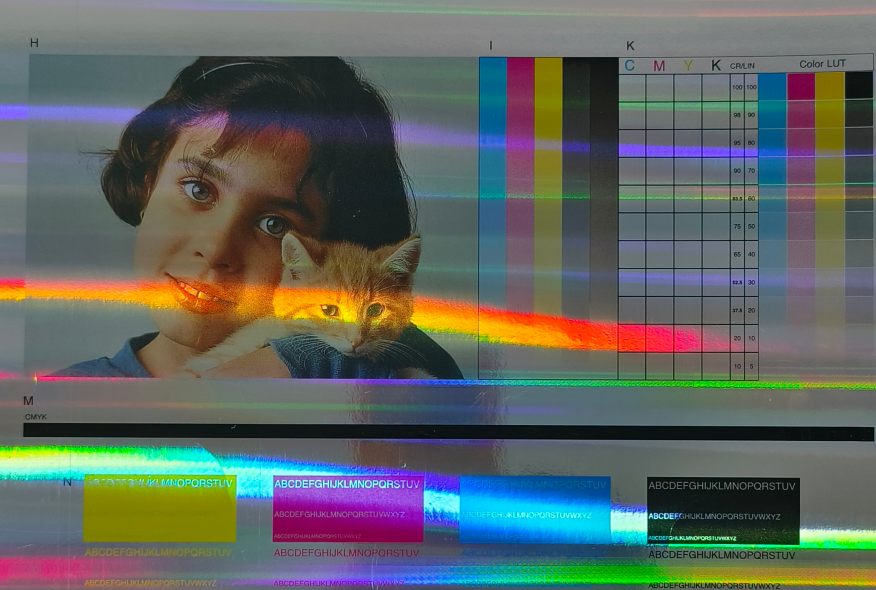

Let's see the following BNK digital printing coating effect.

Rub-resistance test

Pink Color Rendition

Colorful Pictures Printing Effect

From the above tests, we can see that using a good primer is so essential in the printing which can truly show the value of the advanced printing machines. And BNK's digital printing primer is a good choice!